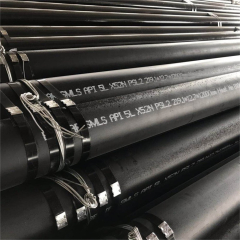

Carbon steel linepipes are used primarily for transporting oil, natural gas, and other fluids in the energy, chemical, and water distribution industries.

They are manufactured to specific standards, such as those from the American Petroleum Institute (API) or American Society for Testing and Materials (ASTM), to meet requirements for strength, pressure, and toughness.

Types of carbon steel line pipes

The primary classification of carbon steel pipes is based on the manufacturing process.

Seamless pipes:

- Manufacturing: Produced from a solid steel billet that is heated and then pierced with a mandrel to create a hollow tube. No welding is involved.

- Characteristics: Known for exceptional strength and resistance to pressure, as there are no welded seams.

- Typical uses: High-pressure and high-temperature applications, such as power plants and high-pressure fluid transportation.

- Specific products: ASTM A106 Grade B (high-temperature service), ASTM A333 Grade 6 (low-temperature service).

- Wall thickness: According to ANSI B36.10 schedule sizes

Welded pipes:

- Manufacturing: Formed by rolling steel plates or coils into a cylinder and welding the seams.

- Characteristics: Cost-effective for larger diameters and applications with lower pressure requirements.

- Typical uses: Water distribution, general construction, and lower-pressure oil and gas transportation.

- Specific products: API 5L Grade B Electric Resistance Welded (ERW) Pipe

- Wall thickness: According to ANSI B36.10 schedule sizes